2020 High quality Erosion Components - Polyurethane Stator And Rotor Of Flotation Machine – Arex

2020 High quality Erosion Components - Polyurethane Stator And Rotor Of Flotation Machine – Arex Detail:

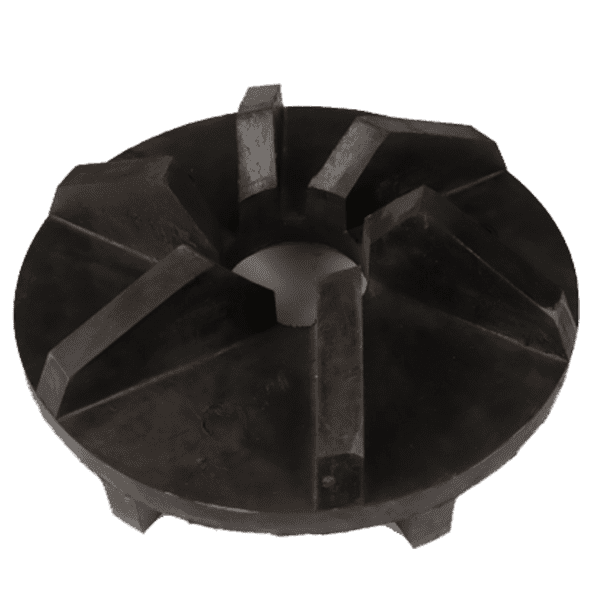

The stator and rotor, mainly used in flotation machine of XJK series, XJQ series, SF series, BF series, KYF series, XCF series, JJF series, BS-K series.

The stator and rotor are the central components of flotation machine, which are mainly applied in benefit of metals or non-metal. Polyurethane stator and rotor belong to one kind of resistant spares of flotation machine with widely properties, as polyurethane has high strength as plastic and as high elastic as rubber. Special material configuration and advanced production technology make Arex polyurethane stator and rotor have more reliable stability. Choosing appropriate model of rotors and stators of flotation machine depending on minerals and slurries.

Features

1. Abrasion resistance

2. Self-lubricity

3. Light weight and easy to install

4.Save energy and electricity

5.Long service life

Wear solution

1.Detecting the wear patterns and rate in the critical area and reinforce the characterize through the working process.

2.By using more rubber or polyurethane material to the place where need most in the whole part. And this will elongate life for working.

3.Giving professional inspection and maintenance when using it by our customers. And getting the regular update report in the operation process, which will supply and increase the plant availability.

Steel skeleton

1.The raw material is using 3CR12 stainless steel bosses, in case of rust and bolt in locking.

2.Welding process reply on ISO standards by experienced workers and keep the balance and accurate when grooving.

3.Customizing work depends on client’s requirement or find the solution from our technology team.

Product detail pictures:

Related Product Guide:

We support our consumers with ideal good quality merchandise and large level provider. Becoming the specialist manufacturer in this sector, we have attained wealthy practical encounter in producing and managing for 2020 High quality Erosion Components - Polyurethane Stator And Rotor Of Flotation Machine – Arex , The product will supply to all over the world, such as: India, Colombia, Spain, Our products are widely sold to Europe, USA, Russia, UK, France, Australia, Middle East, South America, Africa, and Southeast Asia, etc. Our solutions are highly recognized by our customers from all around the world. And our company is committed to continually improving effectiveness of our management system to maximize customer satisfaction. We sincerely hope to make progress with our customers and create a win-win future together. Welcome to join us for business!

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.