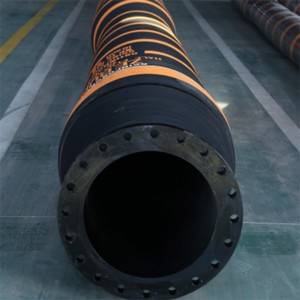

Flexible Slurry Rubber Hose

Industrial Rubber Hose/Rubber Pipeline

Structure & Material

Industrial rubber hoses are heavy-duty, flexible tubes made from synthetic rubber composites. The outer layer is reinforced with high-tensile materials (e.g., braided steel or textile) and often wrapped in protective plastic film or color-coded tape (e.g., green bands with white text). Critical parameters like WP 300 PSI (Working Pressure) and BP 900 PSI (Burst Pressure) are clearly labeled to ensure safe operation.

Key Features

Flexibility & Durability: Designed to endure bending, abrasion, and harsh environments (e.g., extreme temperatures, chemicals).

Pressure Resistance: Multi-layered construction ensures stability under high-pressure conditions.

Easy Integration: Compatible with split flanges via bolted connections for rapid deployment.

Applications

Essential in industries such as oil and gas, mining, construction, and chemical processing for transferring liquids, gases, or granular materials.

Combined System Advantages

The pairing of split flanges and rubber hoses provides a versatile, maintenance-friendly solution for industrial fluid systems. The flange’s split design simplifies repairs, while the rubber hose’s flexibility accommodates dynamic operational demands.

The flexible slurry rubber hose is compounded by NR, BR and SBR compound synthetic rubber. It is using high tensile strength fabrics with steel ring as skeleton of reinforcement.

The flexible rubber hose always being installed in between the pump and cutter of the dredger, which bears negative working pressure during the sucking process of slurry.

The flexible rubber hose & Armored hose, with HB steel ring inside, is suitable for transfer of abrasive slurries, mineral processing plants, tailings lines, sand and gravel. Also available in custom designs for specialty applications such as fluids or slurries containing chemicals, acids and hydrocarbons.

End connections

Fixed Flange, Beaded End Swivel Flange, Full Spigot Fixed Flange, Full Spigot Swivel Flange, Double Flange, Plain Cut End, Full Spigot Custom (eg, Grooved, Coupling, etc).

End material

Carbon Steel, Stainless Steel, Exotic Alloy (consult factory for special requirement).

Pressure rating

Up to 5000kPa as standard (consult factory for special requirement).

Temperature rating

-30°C to +75°C as standard (consult factory for special requirement).

|

Size(inch) |

I.D. (mm) |

W.P. (bar) |

Length (meter) |

|

8 |

200 |

15-20 |

11.8 |

|

10 |

250 |

15-20 |

11.8 |

|

12 |

300 |

15-20 |

11.8 |

|

16 |

400 |

15-20 |

11.8 |

|

20 |

500 |

15-20 |

11.8 |

|

24 |

600 |

15-20 |

11.8 |

|

26 |

650 |

15-20 |

11.8 |

|

30 |

750 |

15-20 |

11.8 |

|

32 |

800 |

15-20 |

11.8 |

|

34 |

850 |

15-20 |

11.8 |

Split Flange (Split-Type Flange)

Structure & Material

A split flange is a two-piece circular fitting typically constructed from durable metal alloys such as stainless steel or aluminum. It features a semi-circular design with bolt holes on both sides for easy assembly and disassembly. The inner surface often includes grooves or threads (e.g., threaded central bore) to ensure a secure connection with pipelines. Split flanges are lightweight yet robust, with a polished metallic finish to resist corrosion.

Key Features

Modular Design: The split structure allows quick installation without requiring pipeline disassembly.

High-Pressure Tolerance: Engineered to withstand industrial-grade pressure (commonly paired with rubber hoses rated for 300 PSI working pressure).

Secure Sealing: Reinforced clamping plates and evenly distributed bolt holes ensure leak-proof connections.

Applications

Widely used in industrial piping systems for fluid transfer (water, oil, chemicals), machinery, and equipment requiring flexible yet durable connections.