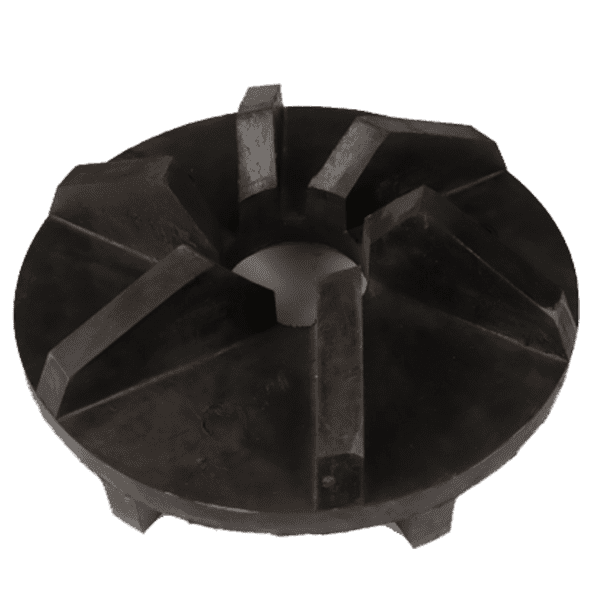

OEM/ODM China Conveyor Idler - Rubber Stator And Rotor Of Flotation Machine – Arex

OEM/ODM China Conveyor Idler - Rubber Stator And Rotor Of Flotation Machine – Arex Detail:

The stator and rotor, mainly used in flotation machine of XJK series, XJQ series, SF series, BF series, KYF series, XCF series, JJF series, BS-K series.

The rotor and stator of the flotation machine are mainly composed by metal skeleton inserts and wear-resistant rubber. Metal skeleton inserts are made of advanced flame cutting and then welded accurately under strict process standards. The strength and balance performance of the skeleton inserts are guaranteed by balancing detection through dynamic balancer. The rubber rotor and stator of flotation machine surface were bonded with wear-resistant rubber and then vulcanized at high temperature.

Our company has 3600 tons of super large flat plate vulcanizer and have the capability to produce the rotor and stator of flotation machine from diameter 200 to 2400 mm. If the demand is more special, we can customize it according to customer requirements.

Properties of rubber material

|

Item |

Unit |

Index |

|

Tensile strength ≥ |

17 |

|

|

Acid (base)coefficient 20%H₂SO₄(20%NaOH)18℃x24h |

0.8 |

|

|

Elongation at break ≥ |

% |

450 |

|

Hardness |

Shore hardness A |

55±5 |

|

Hot air aging coefficient≥90℃x24h |

0.75 |

|

|

Abrasion loss |

cm³/1.61km |

0.7 |

|

Metals and layer adhesion≥ |

MPa |

2.5 |

|

Tearing permanent deformation≤ |

% |

30 |

|

Oil coefficient 20# oil 100℃x24h |

% |

±10~5 |

Features

1. Abrasion resistance

2. Tear resistance

3. Impact resistance

4. Chemical stability

5. Long service life

Wear solution

1.Detecting the wear patterns and rate in the critical area and reinforce the characterize through the working process.

2.By using more rubber or polyurethane material to the place where need most in the whole part. And this will elongate life for working.

3.Giving professional inspection and maintenance when using it by our customers. And getting the regular update report in the operation process, which will supply and increase the plant availability.

Steel skeleton

1.The raw material is using 3CR12 stainless steel bosses, in case of rust and bolt in locking.

2.Welding process reply on ISO standards by experienced workers and keep the balance and accurate when grooving.

3.Customizing work depends on client’s requirement or find the solution from our technology team.

Product detail pictures:

Related Product Guide:

We usually keep on with the principle "Quality To start with, Prestige Supreme". We've been fully committed to offering our purchasers with competitively priced excellent solutions, prompt delivery and skilled support for OEM/ODM China Conveyor Idler - Rubber Stator And Rotor Of Flotation Machine – Arex , The product will supply to all over the world, such as: Belize, Salt Lake City, Lisbon, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.