Original Factory Silicone Rubber Hose - Polyurethane Lined Steel Pipe – Arex

Original Factory Silicone Rubber Hose - Polyurethane Lined Steel Pipe – Arex Detail:

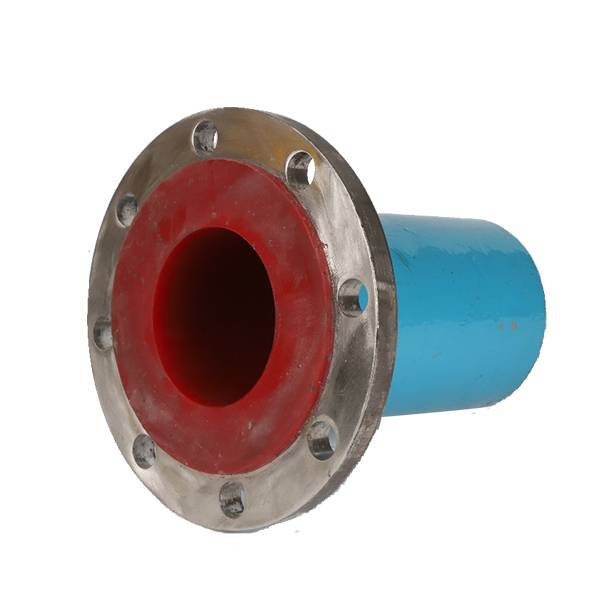

Polyurethane lined steel pipe is a high wear resistant pipeline product, which is widely used in mineral processing pipelines and tailing transmission pipelines. Fossil-fuel power station use the pipeline for coal and ash removal systems, as well as for oil, chemical, cement and grain industries.

Features

1. Wear-resistant

2.Prevent Scaling

3.Corrosion Resistance

4. Resistance to hydrolysis aging

5. High Elasticity

6. Resistance to Mechanical Shock

7. Self-lubrication

Arex selects the premium master batch with nano-modified approach to strength the polyurethane material’s function. It makes the polyurethane lined products with more steady chemical structure and demonstrate its adaptability in the working circumstance.

The polyurethane lined steel pipe, as one of domestic patent of mining products in Arex, is popular and being used by our mining customers.

Comparison of properties between common polyurethane and nano-modified polyurethane

|

Testing item |

Common polyurethane test index |

(nano-modified) polyurethane |

|

Tensile strength |

15-21MPa |

19-28MPa |

|

300%setting the stretching strength |

8-10MPa |

11-13MPa |

|

Tensile elongation |

400-500% |

400-500% |

|

Break permanent deformation |

5-8 |

5-8 |

|

The tear strength |

5MPa/cm |

6.8MPa/cm |

|

Shear strength |

6MPa/cm² |

8.1MPa/cm² |

|

Avulsion intensity |

7.5MPa/cm² |

11MPa/cm² |

|

Peel strength |

1.4MPa/2.5 cm² |

2.1MPa/2.5 cm² |

|

Akron abrasion |

0.045cm³/1.61km |

0.008cm³/1.61km |

|

Low temperature brittleness |

-42 |

-70 |

|

Hardness (shaw A) |

60-100 |

60-100 |

|

The density |

1.12 |

1.12 |

Product detail pictures:

Related Product Guide:

Assume full accountability to fulfill all demands of our purchasers; attain continual advancements by marketing the advancement of our clientele; grow to be the final permanent cooperative partner of purchasers and maximize the interests of purchasers for Original Factory Silicone Rubber Hose - Polyurethane Lined Steel Pipe – Arex , The product will supply to all over the world, such as: Manchester, Sri Lanka, Pretoria, we have all day online sales to make sure the pre-sale and after-sale service in time. With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.