Best quality Rubber Gas Line Hose - SAG/AG/Ball/Rod Milling Rubber Liners – Arex

Best quality Rubber Gas Line Hose - SAG/AG/Ball/Rod Milling Rubber Liners – Arex Detail:

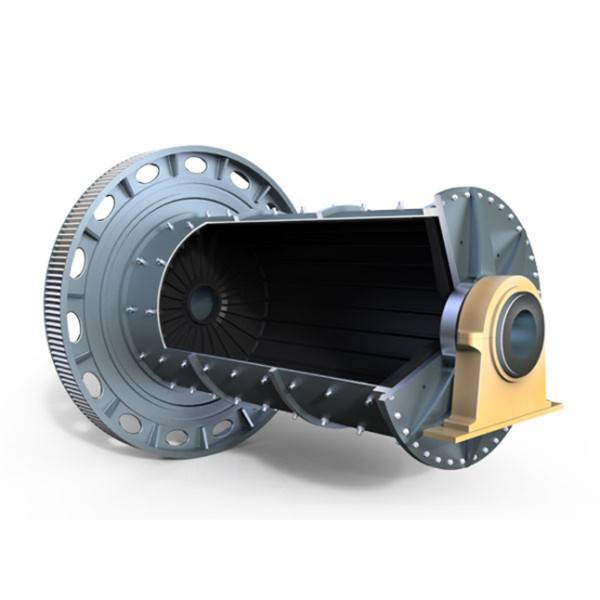

The rubber liner is gradually replacing the manganese steel liner. It can bear strong impact of resistance. The yield of your grinding circuits is highly dependent on your mill’s rubber liner. Select right of your rubber liner supplier carefully will make sure your milling process runs at maximum capacity and availability.

Rubber liners is usually suitable for wet grinding, the temperature is not higher than 80 degrees of normal work, but for high-temperature dry grinding, strong acid and Alkali resistance, oil resistance and other special environment, need to be explained in advance by separate design formula and custom made, in addition, the storage process must be placed in indoor proper custody, it intends the rubber liners to prevent outdoor exposure under the high temperature and rain.

According to the purpose, the rubber liners is divided used in:AG, SAG, ball, pebble, rod & batch mills, FGD, SMD and continuous mills.

According to the shape, it is divided into overflow type, grid type and multi-bin type, which can meet the requirements of one-stage rough grinding and two-stage fine grinding.

We can customize all kinds of high-quality and high wear-resistant rubber liners according to the needs of each customer.

Features

1. Low energy consumption

2. High wear resistance

3. Low maintenance

4. Impact resistance

5. Low noise

6. Easy to install

7. Corrosion resistant

8. Saving of steel balls

① Lifter Bars

Lifter Bars are available in a range of widths, heights and rubber or composite profiles. Lifter Bars incorporating a steel insert are designed to provide maximum impact and abrasion resistance.

② Filling & Corner Segments

Filling and Corner Segments are designed to lock the Head Plates and Grate Plates into position and stop material racing in the corners.

③ Head Plates

Rubber Head Plates are available in various designs to combat sliding abrasion. Head Plates are designed to facilitate ease of installation and handling

④ Grate Plates

Heavy- duty Grate Plates designs are available for large mills. The elastic property of rubber allows for smaller slots than steel grates whilst eliminating blind problems. Available in a range of aperture sizes.

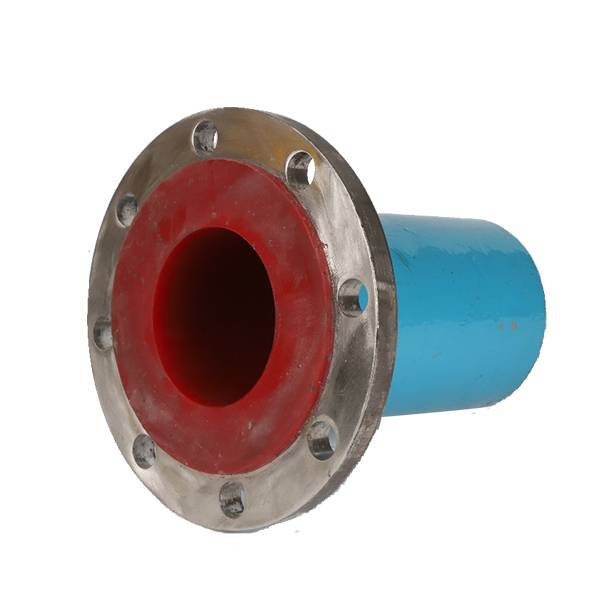

⑤ Centre Cones & Trunnion& Bell Mouth Liners

Centre Cones can be designed in segments for ease of installation.

Trunnion& Bell Mouth Liners

Trunnion Liners are manufactured from a fabricated steel base, which are then rubber lined. Loose steel-backed rubber liners are also used in larger Trunnion and Bell Mouth linings.

⑥ Outer Pulp Lifters

⑦ Inner Pulp Lifters

Rubber lined Pulp Lifters are designed to provide the correct discharge of the pulp through the mill in order to minimize bottle- necks.

⑧ Shell Plates

The thickness of the shell plates can vary in order to increase mill capacity and/ or liner life. The width is designed for optimum protection from the lifter bars.

Physical properties index

| Performance | Unit | Index |

| Breaking strength | MPa≥ | 18 |

| Elongation at break | %≥ | 420 |

| 300%of constant stress | MPa≥ | 12 |

| Hardness | Shore A(degree) | 64-68 |

| Akron abrasion | cm³/1.61km | 0.1 |

| Impact elasticity | %≥ | 45 |

| Tearing permanent deformation | %≥ | 10 |

| The adhesion of rubber and metal | KN/m | 6 |

All of dates belongs to normal standard and consult factory to get the special customization.

Product detail pictures:

Related Product Guide:

To create far more benefit for customers is our company philosophy; customer growing is our working chase for Best quality Rubber Gas Line Hose - SAG/AG/Ball/Rod Milling Rubber Liners – Arex , The product will supply to all over the world, such as: Austria, America, France, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our products. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best for you always.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.